Pavement Analysis

Data Collection & Pavement Management

Pavement management is the process of planning the maintenance and repair of a network of roadways or other paved facilities in order to optimize pavement conditions over the entire network. [Source: Wikipedia]

The process starts with data collected about pavement surface conditions. At MDT, the Pavement Management Unit conducts an annual road condition survey utilizing two Data Collection Vans (Figure 1) and a Skid Truck in combination with trailer (Figure 2).]

The Data Collection Vans (DCV) collect both video log and laser images of the road surface used for analysis. Workstations in the office process and analyze the data which reveals information about road smoothness, rutting and cracking. The DCV collects data at speeds of 60 M.P.H. or less.

Skid resistance is the force developed when a tire that is prevented from rotating slides along the pavement surface. (Source: Highway Research Board, 1972)

The skid truck and trailer test the road surface for skid resistance or friction. Network level skid data is collected as time allows on a two-year cycle. Project level testing is provided upon request for a specific treatment study. The skid truck collects data at a speed of 40 M.P.H. or less.

The analyzed data for cracking, rutting and smoothness is imported into MDT's Pavement Management System (PvMS) for overall pavement condition analysis. The Pavement Management Unit provides analysis tools used by management and engineers in making budget decisions and cost-effective selections of Maintenance, Rehabilitation, and Reconstruction strategies on a network basis to enhance the longevity and safety of the highway.

Non-Destructive Tests

While it is sometimes necessary to collect samples from the pavement, MDT tries to avoid core sampling when a non-destructive method will do.

Non-destructive is a term used to describe tests conducted on an existing pavement structure that do not require subsequent maintenance work to return the pavement to its pre-testing state. Non-destructive tests are preferred to those which require subsequent maintenance to repair damage left behind by the test. MDT's Non-destructive Testing Unit conducts tests that don't damage the pavement. In this unit, we have 2 data collection trucks that collect information on the roadway using falling weight deflectometers and also ground penetrating radar.

- Falling Weight Deflectometer

- A falling weight deflectometer (FWD) drops a weight from a specified height onto a load plate that is in contact with the pavement surface. This emulates traffic on the road and measures the response of the pavement to the load. This method tells us something about the stiffness of the roadway.

- Ground-penetrating Radar

- Ground penetrating radar (GPR) is an electromagnetic energy signal that penetrates through the pavement's subsurface. GPR units have an antenna capable of transmitting and receiving signals. Return signal strength varies based on subsurface condition.

Surface Improvements

Data collected by MDT's various trucks is used to plan the safest and most cost-effective repairs.

Cross Slope

Pavement cross slope is an important cross-sectional design element. The cross slope drains water from the roadway laterally and helps minimize ponding of water on the pavement. This prevents maintenance problems and also minimizes icing from occurring on poorly drained pavement. On roadways with curbed cross sections, the cross slope moves water to a narrower channel adjacent to the curb, away from the travel lanes, where it can be removed. Read more...

Rut Repair

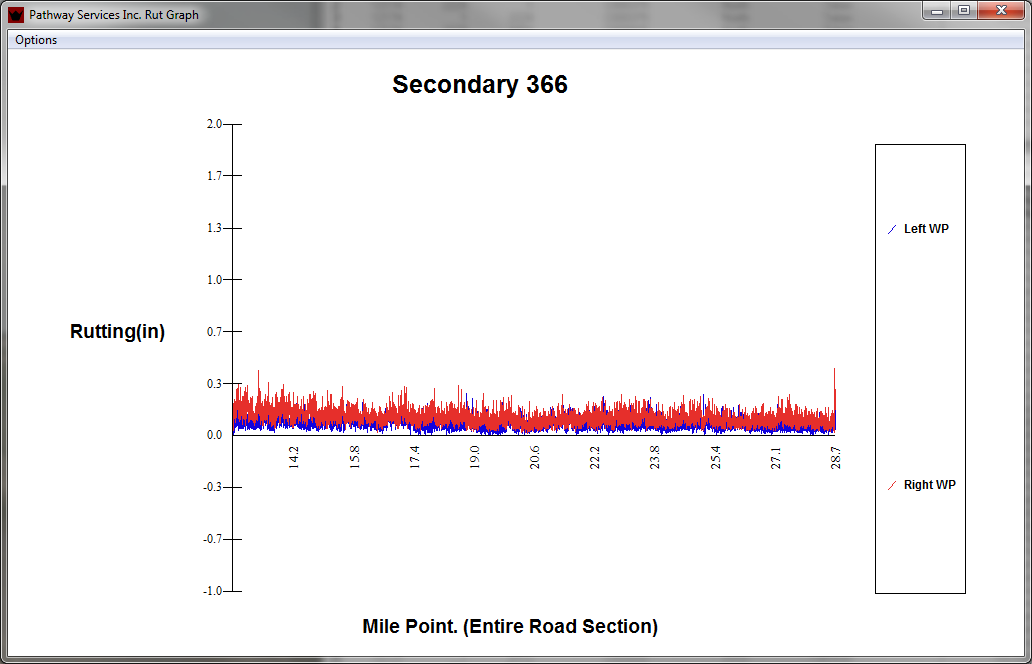

Rutting is a major form of pavement distress in asphalt pavements. It is a form of deformation of the pavement surface along the wheelpaths. The main concern with rutting has been related to driving safety. If ruts fill up with water in wet weather, they can potentially lead to vehicle hydroplaning and loss of skid resistance.

- Chip seal

- Road surfaces wear down and become smooth over time. Chip sealing restores road texture.

- Micro-surfacing

- Rut depth can be reduced by a cost-effective surface treatment called micro-surfacing. The micro-surfacing treatment (a mixture of crushed aggregate, polymerized asphalt emulsion, Portland cement, and an admixture) is applied in one or more coats. It is more cost effective than chip sealing and has been shown to be effective in mitigating rutting two years after construction.

Want to Learn More?

The Federal Highway Administration's Office of Safety website is an excellent resource for anyone interested in how safety enters into the entire life cycle of a roadway from planning to maintenance.

The Pavement Edge

The Safety Edge is a simple but effective solution that can help save lives by allowing drivers who drift off highways to return to the road safely. Instead of a vertical drop-off, the Safety Edge shapes the edge of the pavement to 30 degrees. Research has shown this is the optimal angle to allow drivers to re-enter the roadway safely. The asphalt Safety Edge provides a strong, durable transition for all vehicles. Even at higher speeds, vehicles can return to the paved road smoothly and easily. The FHWA's goal is to accelerate the use of the Safety Edge technology, working with States to develop specifications and adopt this pavement edge treatment as a standard practice on all new paving and resurfacing projects.