This project was nominated as High Value Research and was selected as a Supplemental Topic Recognition winner in 2022.

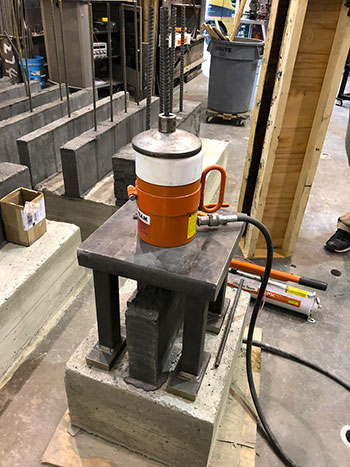

Ultra-high performance concrete (UHPC) has mechanical and durability properties that far exceed those of conventional concrete. However, using UHPC in conventional concrete applications has been cost prohibitive, with commercially available/proprietary mixes costing approximately 30 times more than conventional concrete. Previous research conducted at Montana State University resulted in non-proprietary UHPC mixes made with materials readily available in Montana. These mixes are significantly less expensive than commercially available UHPC mixes, thus opening the door for their use in construction projects in the state. The MDT Bridge Bureau is interested in using UHPC in field-cast joints between precast concrete deck panels. The use of UHPC in this application will reduce development lengths, and subsequently reduce the requisite spacing between the decks and improve the overall performance of the bridge. The research will build on the non-proprietary UHPC research completed in Phase 1 of this project and focus on ensuring the successful application of this material in these field-cast joints. Specifically, this research will investigate several items related to the field batching of these mixes, and the potential variability in performance related to differences in constituent materials. Further, rebar bond strength and the subsequent effect this has on development length will be investigated.

Materials and Mixing

MT-UHPC Overview and Best Practices

Technical Brief

MDT Research Technical Brief: Putting Montana’s Ultra-High Performance Concrete to Work

Phase I

Final Report

Final Presentation

Project Summary Report

Phase II

Final Report

Final Presentation

Project Summary Report

Poster

Phase III

Final Report

Final Presentation

Project Summary Report

Implementation Report

Performance Measures Report

Poster